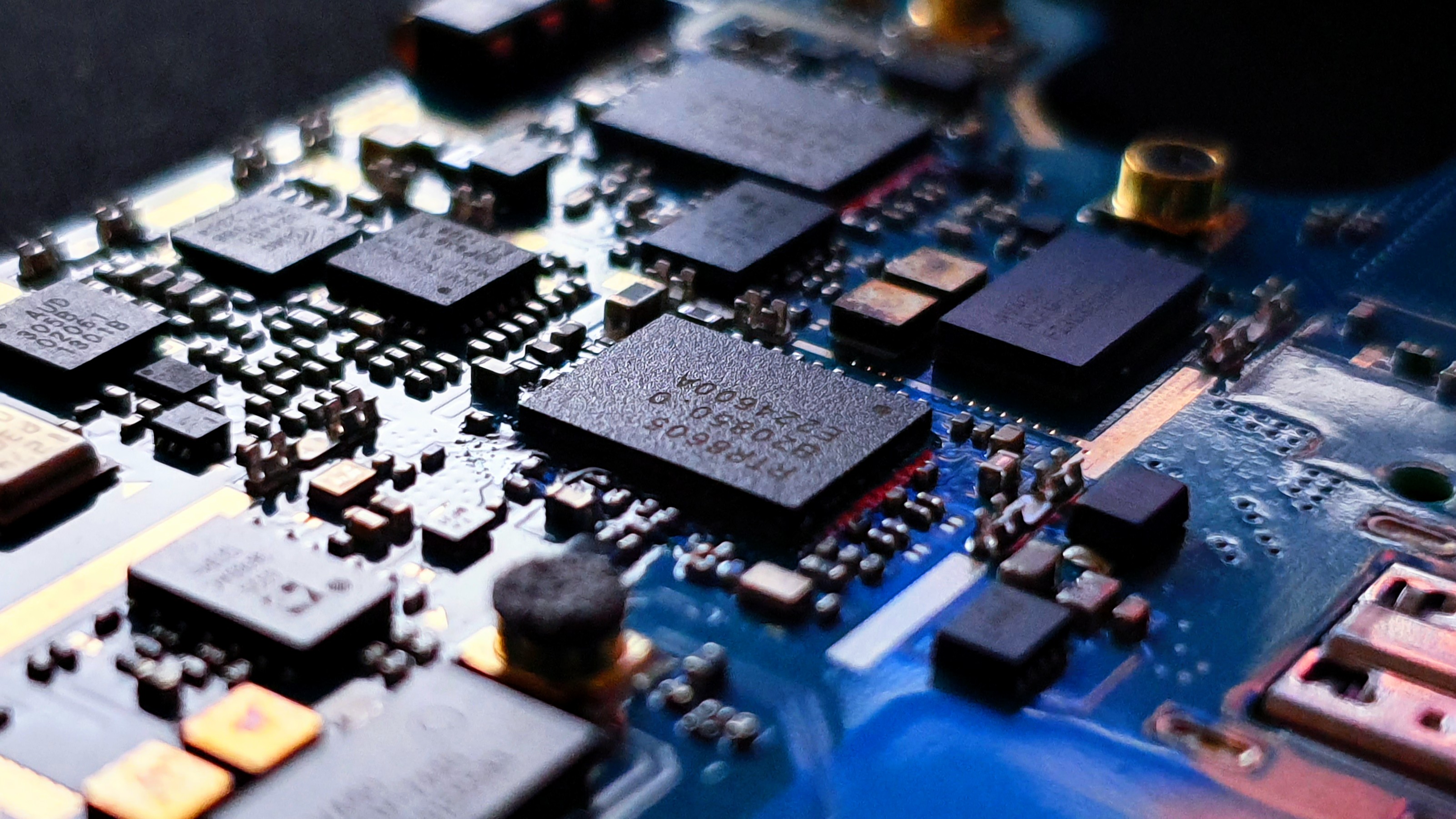

7 PCB design trends to watch out for in 2022

The PCB industry is growing and, as a whole, is fascinating for many people. The EE Times Europe reports that the predicted CAGR for the worldwide (PCB) market from 2021 to 2026 is 3.3%. It was estimated to be worth $70.92 billion in 2020 and is anticipated to reach $86.17 billion in five years. It’s constantly changing, with new materials and technologies coming out every year. Some of those changes are driven by trends in technology, while others come from the manufacturers themselves. In this article, we’ll look at some of the PCB design trends that will be most important over the next few years.

Biodegradable PCBs

A biodegradable PCB is a board made of natural materials like paper or cotton. These PCBs are used in the medical industry as they can be easily disposed of and do not leave behind toxic residue. Biodegradable boards are also commonly used in food packaging and other products that require long shelf lives.

Biodegradable PCB is a relatively new concept, with several manufacturers already producing bioplastic boards that can be disposed of easily or recycled. Examples include the boards made by one of the companies, which are made from wood pulp cellulose fibers. When disposed of properly, these can be dissolved in water within two days without leaving any toxic residue in landfills or oceans.

High-Density Interconnect (HDI) PCBs

High-Density Interconnect (HDI) PCBs are used in high-current and high-speed applications. They can be found in military electronics, aerospace electronics, and, most commonly, industrial applications.

High-density interconnects (HDI) PCBs have higher density interconnections than conventional multi-layer printed circuit boards. As a result, HDI boards offer a high level of integration between components while providing an excellent thermal management solution.

HDI technology allows manufacturers to create more compact electronic systems that consume less power than their predecessors. As a result, it makes them ideal for use in areas where space is limited, or weight is critical. These include medical devices or avionics equipment where size reduction is essential for safety reasons, such as aircraft cabins.

Flex PCBs

Flexible PCBs are used in various applications like medical devices, wearables, and IoT devices. They are also used in the aerospace, industrial, and automotive sectors. In addition, flexible PCBs find use in smart cards, where they have to be designed with great care. The product must be flexible enough for the user to carry it easily and is sufficient for proper functioning.

Flexible PCB designers should remember that a flexible circuit board has several limitations compared to a rigid one. The rigid ones have lower strength and higher susceptibility to damage when flexed repeatedly or during storage conditions like extreme temperatures or humidity levels.

In addition, it can cause components such as resistors to malfunction due to too much heat generated by these components. That could be because of the lack of ventilation spaces inside them, which would otherwise dissipate such heat. Therefore before designing your next project, choose an experienced PCBA company. They will help you create something remarkable with the best PCB design services they have to offer.

Moisture Sensitive Devices (MSDs)

It’s not just the size that matters, and it’s what you do with it. It is now possible for PCB designers to create smaller and more compact devices by making use of MSD-related innovations.

There are many examples of MSDs, such as integrated circuits (ICs), for which the market is predicted to grow from 2021 to 2022 by more than ten percent, reaching 510.96 billion US dollars, according to satista.com. MSDs also include resistors and capacitors, inductors and transformers in electronic systems. In addition, some microelectromechanical systems (MEMS) also fall into this category due to their size sensitivity.

Designers must understand how these components behave when moisture or water condensation is exposed. They have to be checked before incorporating them into a board design. So they can appropriately place them on the board without risking damage from corrosion caused by liquids present around them during use.

Quick Turn PCB Manufacturing

The next trend that we can expect to see in 2022 is the rise of Quick Turn PCB Manufacturing. This manufacturing term describes the process of sending your design and receiving a prototype within 24 hours. Many people think quick-turn PCBs are only good for prototyping, but this isn’t true. They can also be used as production PCBs, and there are companies out there that specialize in quick-turn PCB manufacturing. There they have high volume facilities set up to produce these boards at a meager cost per unit.

What’s interesting about this type of manufacturing is that it gives electronics companies an edge over their competitors. That is because they can build products faster than everyone else, which means they can get their products on store shelves before anyone else.

However, if you’re considering using quick-turn PCBs, then there are some things you should watch out for:

- Ensure your design works before choosing this option, and avoid using cheap components.

- Don’t try and save on shipping costs by sending all the parts separately when designing with them. Instead, always use one distributor throughout the entire production process, so nothing gets lost along the way.

Internet of Things PCBs

The Internet of Things (IoT) is the concept that everything can be connected to the internet. It includes your phone, laptop, and tablet. IoT PCBs are used in smart homes and smart cities that use sensors to collect data on air quality, traffic congestion, garbage collection, etc. They are also used in smart cars, which use sensors to detect road conditions or parking spaces through wireless communication.

Smart factories use IoT PCBs to monitor production machinery for efficiency improvements. These include energy consumption reduction by monitoring temperature levels accurately. So those cooling systems can be turned off when not needed. IoT healthcare involves using sensors attached directly to patient bodies or implanted inside them. It sends real-time information about their health status via wireless communications without human interaction. It helps doctors monitor patients remotely and decide treatment plans accordingly without physical contact.

High Power Boards

High power boards are a type of PCB designed for applications requiring high power. These boards are used in applications such as medical devices, industrial equipment, and military equipment.

The most common materials used to create high-power boards include FR-4 and Rogers materials. These materials have similar characteristics, making them both suitable for high-power PCBs. However, you should choose your board’s material based on what your manufacturer has available at their facility. Or also offer custom services where you can specify the type of material you want your board to be made from before fabrication begins.

Suppose you choose to go with FR-4 material. In that case, several options are available, including single-sided designs with no plated through holes. Double-sided designs with plated through holes located at different distances between layers. So that interconnections may be made between adjacent layers without compromising their integrity.

These are the PCB Designing Trends to Checkout in 2022

PCB design trends are constantly moving, so it’s essential to know the latest trends. In this article, we looked at some of the most prevalent PCB design trends you should keep an eye on as we approach 2022.

These trends are based on the needs of both the PCB design and manufacturing industries. As an engineer, you must understand what your customers need so that you can deliver the products they want. The same goes for manufacturers. They need to know what customers are looking for to ensure they can fill those needs with each new product launch.