Decarbonisation through electrification – a comprehensive overview

Although climate change is one of the biggest challenges of our time, it holds immense opportunities for creative and innovative solutions. Vattenfall has a unique position to seize these opportunities and transform itself and other emitting industries on an unprecedented scale.

Vattenfall’s goal to enable fossil-free living within one generation means making its own energy mix 100 per cent fossil free through large investments in fossil-free energy and phasing out fossil energy sources. But it also means looking beyond Vattenfall’s own production, to how the company can enable fossil freedom in other sectors in the European home markets and beyond.

Together we can make the necessary transition

“On a global scale, demand for carbon-intensive materials and products like concrete, steel and plastic, with which we have built our modern societies, shows no signs of slowing down,” says Vattenfall’s Head of Industry Decarbonisation in Staff Function Strategic Development, Mikael Nordlander. “Industry, along with transport, stands for the largest share of global CO2 emissions today, and globally, the challenge of limiting the climate impact from our way of living, working and producing remains. However, a report from 2020 by the Energy Transition Commission (ETC) shows that technically and financially it is indeed possible to decarbonise our society.”

According to the report, achieving a net-zero carbon emission economy will have only a negligible impact on living standards and on growth between now and 2050. Actually, full decarbonisation will cost less than 0.5 per cent of global GDP according to ETC, while ”The Economics of Climate Change: The Stern Review” has estimated the costs to between 5 and 20 per cent, if we do nothing.

The growing demand for sustainable solutions and products from customers is certain to spur a new generation of materials and industries. As part of Vattenfall’s sustainable business strategy, forces should therefore be joined with organisations and companies with innovative ideas, competences and financial sources across the borders in Vattenfall’s value chains. Obviously, the energy transition and the development of a fossil-free society will not materialise overnight, but it is the only direction possible.

Electrification as an enabler of fossil-free living

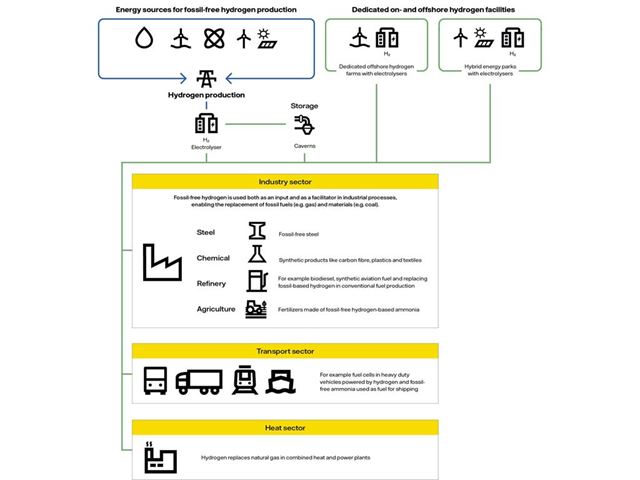

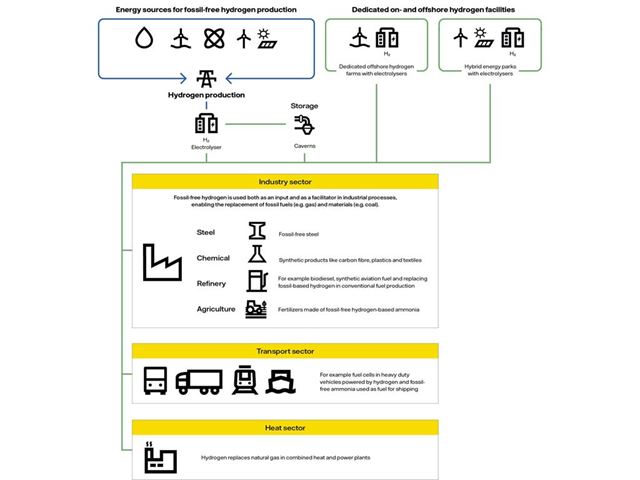

Ever since the first electrons were put to work in the 19th century, electricity and fossil fuels have been a main driver for social and economic progress. And now, together with the decarbonisation of the energy sector itself, electricity will be a key tool in the transformation towards fossil-free industrial sectors and societies. Electricity can be utilised to reduce or eliminate carbon emissions in industry and society by direct electrification, where it directly replaces a fossil-based energy source, or by indirect electrification, mainly by introducing fossil-free hydrogen in industrial processes or in the transport or heat sectors. A prerequisite for electrification to be a driver for decarbonisation is obviously that the energy supply is based on fossil-free electricity such as wind, solar, hydro or nuclear power – all energy sources in Vattenfall’s portfolio.

“So, we have a plentiful supply of the basic fossil-free commodity that is necessary for us to transform not only our own business but vast parts of our societies,” Nordlander explains. “Our task is now to put our minds together with especially the transport and industry sectors to identify, develop and deploy innovative ways of electrifying activities either directly or indirectly.”

Hydrogen – a solution in those places where direct electrification is not possible

Vattenfall considers indirect electrification through fossil-free hydrogen as an important solution to decarbonise the value chains of in particular heavy-emitting industries, heavy transport and Vattenfall’s own fleet of heat power plants. Vattenfall sees a potential to contribute throughout the entire value chain from generation and delivery of fossil-free electricity to, in some cases, production and storage of hydrogen.

To Mikael Nordlander the role of hydrogen is clear: “Vattenfall is actively contributing to shaping a strong European hydrogen economy, where large-scale hydrogen production based on affordable fossil-free electricity is a key pillar for a successful energy transition. Although fossil-free hydrogen production is not yet always commercially viable and hydrogen will not become the solution to reducing CO2 emissions in all areas, it has the potential to decarbonise processes where direct electrification is not possible. This is fundamental for reaching the climate targets from the Paris Agreement as well as our own ambitious goal of enabling a fossil-free life.”

Partnering for a fossil-free future

Vattenfall is participating actively in various projects and development initiatives across all its markets to further drive the implementation of fossil-free electricity (see detailed list in the Vattenfall partnerships and hydrogen projects box).

Direct electrification partnerships have already been formed with companies in the Swedish mining industry and in the transport sector and Vattenfall is owning and operating one of Europe’s largest charging networks, InCharge, for electric cars. Also shipping and aviation are areas where Vattenfall is engaging in partnerships and innovation activities around direct electrification.

When it comes to indirect electrification, Vattenfall is driving the development towards utilisation of fossil-free hydrogen tailored to the energy-intensive industry. This is done in several pioneering projects through partnerships in which each stakeholder contributes with its unique capabilities. Examples of this are the production of fossil-free steel; a strategy study for large-scale biofuel production; and development of plans at Vattenfall’s Moorburg power plant in Hamburg for a facility to produce hydrogen from wind and solar power to decarbonise facilities in the harbour area.

In the heating sector, Vattenfall is among other things working to establish whether our CHP plant Marzahn in Berlin can be used for testing the application of hydrogen in power plants.

“We see many more innovative opportunities of electrification in other heavy-emitting industries also,” says Mikael Nordlander. “In the chemical sector, this can be done through the use of fossil-free hydrogen and captured carbon dioxide for the production of methanol for example – a basic building block for materials such as plastic and carbon fibre. In the agricultural sector, the production of ammonia used for fertilisers can be decarbonised by fossil-free hydrogen, and the aviation sector offers opportunities, where replacing fossil feedstock with electricity for the refining of biofuels or production of synthetic fuels from CO2 can decarbonise the production of kerosene.”

Wind, solar and electrolysers

In the Netherlands, Vattenfall is also developing a project, which can potentially produce 100% renewable hydrogen onshore by connecting wind and solar electricity generation directly to an electrolyser and a battery.

Dedicated offshore hydrogen parks combining wind turbines and electrolysers could become one of the backbones of the hydrogen economy. Thanks to its high number of full-load hours, wind is particularly well suited for the production of fossil-free hydrogen. However, the fact that many future wind sites will be located further out at sea will make electric transmission via cable very expensive. Energy transmission via hydrogen piping will thus become the more attractive solution for these types of farms.

Collaboration across borders is key

Decarbonising Vattenfall’s value chains through collaboration across companies, organisational, functional, societal and geographical borders is a complex challenge. Each country and market have their own specific challenges and strategies on how to move forward, demanding industry to even more actively search for the best fitting coalitions in order to create a new generation of fossil-free products and services. Working together in sometimes unexpected partnerships can increase the innovation potential along any step of the value chain, from design to delivery of intermediate and finished products or services, and to the way in which by-product streams are managed. Not in the least, working together also means that financial as well as non-financial risks can be better mitigated throughout the chain. The journey towards fossil-free living is well underway.

Fossil-free hydrogen – sources and applications

Vattenfall partnerships and hydrogen projects

BOLIDEN: Vattenfall has a collaboration with Boliden on direct electrification of mines and smelters, which also includes battery solutions aimed at supporting the electricity grid and optimising electricity consumption.

KAUNIS IRON: Vattenfall and Kaunis Iron have a partnership concerning directly electrified fossil-free mining operations at the iron ore mine in Pajala, in Northern Sweden. The collaboration involves business solutions to reduce the need for fossil fuels, such as electrified iron ore and passenger transports.

HYBRIT: Vattenfall’s most advanced industry decarbonisation project is the fossil-free sponge iron project HYBRIT for producing fossil-free steel by means of hydrogen. It is run together with our Swedish partners, steel company SSAB and mining company LKAB with support from the Swedish Energy Agency.

Biofuel production: In a strategy study for large-scale biofuel production, Vattenfall is exploring opportunities to replace fossil fuels in the production process. This is done together with Sweden’s largest refinery company Preem.

Green Hydrogen hub Moorburg: At the Hamburg Moorburg power plant, Vattenfall has joined hands with Shell, Mitsubishi Heavy Industries and the municipal company Wärme Hamburg. The intention of the partnership is to develop plans for a facility to produce hydrogen from wind and solar power and utilise it in the vicinity.

Hydrogen for heating: In the heating sector, hydrogen has the potential to reduce CO2 emissions, if used as an alternative to gas. Vattenfall is among other things working with Siemens Energy to establish whether our CHP plant Marzahn in Berlin can be used for testing the application of hydrogen in power plants.

The chemical sector: In the chemical sector Vattenfall sees many more opportunities of electrification by producing methanol, a feedstock of materials such as plastic and carbon fibre, through the use of fossil-free hydrogen and captured carbon dioxide.

The agricultural sector: In the agricultural sector, the production of ammonia used for fertilisers can be decarbonised through the use of hydrogen.

The aviation sector: This sector also offers opportunities, as replacing fossil feedstock with electricity can decarbonise the production of kerosene. Vattenfall is partner in the ‘Hemweg Consortium’ which among other things is focused on using hydrogen for making aviation fuel.

The transport sector: Vattenfall is owning and operating one of Europe’s largest charging networks, InCharge, for electric cars including partnerships with municipalities, car manufacturers, grid operators, private companies and housing associations.

Vattenfall onshore combined wind and hydrogen facilities: At the wind farm Slufterdam next to the harbour of Rotterdam, renewable electricity can be used directly to produce hydrogen and thereby avoid curtailment, and in Northern Netherlands, Vattenfall aims to produce 100% renewable hydrogen by connecting wind and solar electricity production directly to an electrolyser and a battery.

Vattenfall dedicated offshore hydrogen parks: Vattenfall believes that cost-competitive fossil-free hydrogen can be achieved by 2030by combining scale, standardisation and innovation in dedicated hydrogen-producing offshore wind farms. Therefore, Vattenfall is investigating several projects and initiatives across Europe and is a founding member of the initiative AquaVentus, which has the ambition to install 10 GW of offshore hydrogen capacity in the German North Sea until 2030.